Microplastics are tiny particles causing a big problem. It is estimated there are some 5.25 trillion pieces of plastic in the ocean. 269,000 tonnes of that plastic floats on the surface but a staggering four billion microplastics per square kilometre litter the deep sea. While bottles, cups, and bags can technically be cleared up (although the scale of the problem makes this very difficult in reality), trying to clean up microplastics is impossible – they’re simply too small. That’s why we’re making a change to how we make our clothes.

Tiny particles, big impact

It’s estimated that around 11 million tonnes of plastic enters the ocean every year, and nearly a million tonnes of this is “primary microplastics”, i.e. plastics that are already less than 5mm in size. 35% of these primary microplastics are plastic microfibres - tiny fibres that have shed from synthetic garments in the wash.

As many as 700,000 plastic microfibres can be released from a single load of laundry, and it’s estimated that 500,000 tonnes of microfibres are released into the ocean via domestic washing annually. When they enter the ocean, these plastic microfibres start to interfere with established marine ecosystems. For instance, zooplankton mistake microfibres for their food, so they eat them and don’t get any of the nutrients they need. The waste plankton excrete provides essential food for other bottom-dwelling species such as worms, crabs, and sea stars, but because the zooplankton aren’t getting the right nutrients, neither are these creatures and so the problem moves up the food chain.

In addition to issues at the seabed, changes in plankton communities at the ocean surface could exacerbate deoxygenation which is caused by climate change, meaning marine organisms are starved of oxygen. Microplastics can also impact aquatic life in myriad other ways such as delaying growth, causing abnormal behaviour, and harming reproduction.

Researchers are still in the very early stages of beginning to understand the scale of the negative impacts of microplastics, but what we already do know is enough to convince us that we do not want to be a part of the problem. That’s why we’re committed to a goal of zero microplastics by 2030 – meaning by that year none of our products will contain, or shed, microplastics. Here’s how we’re working towards it.

Natural fibres

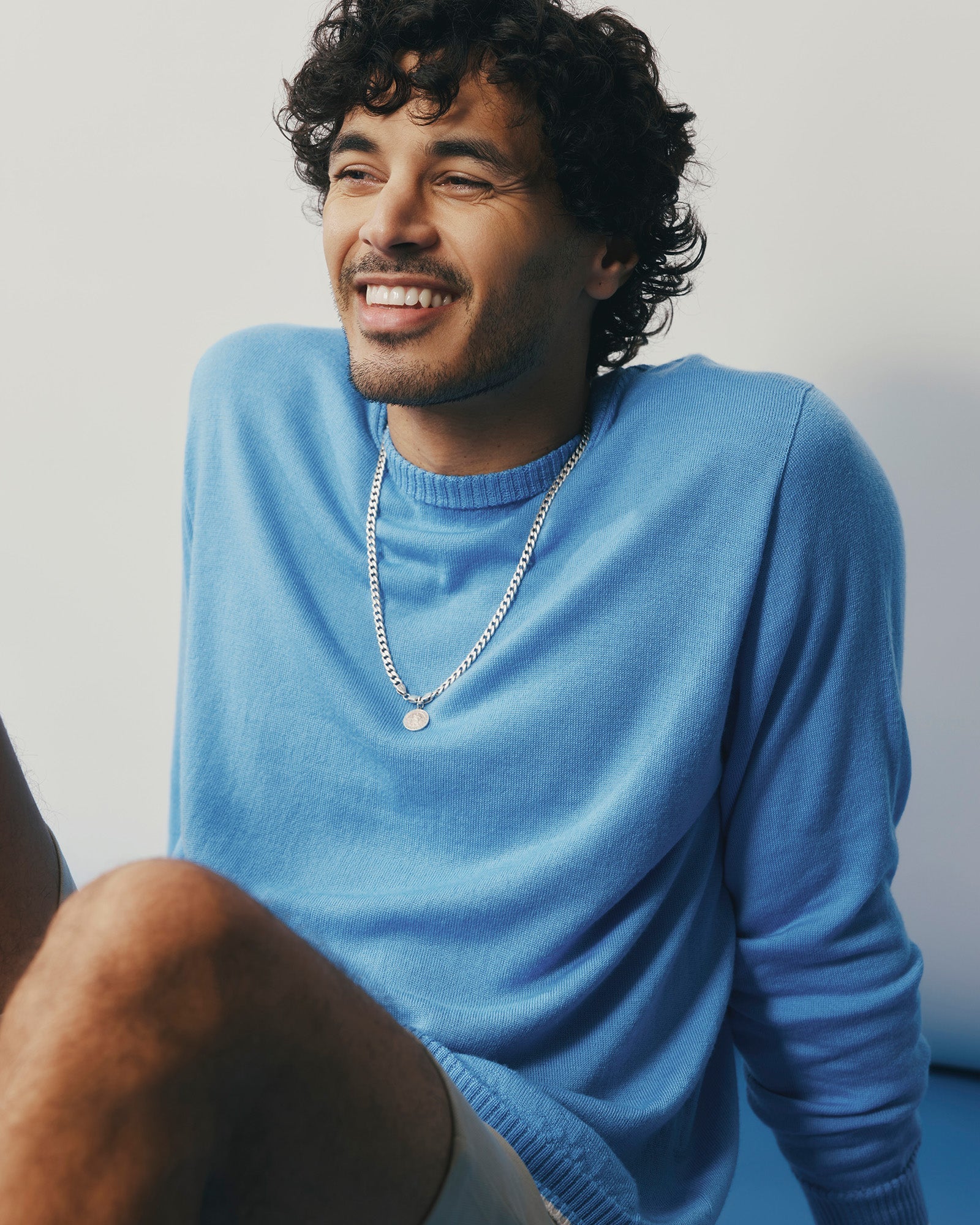

93% of our products are made from 100% natural fibres, this includes everything from 100% cotton shirts to Ecopossum knits made from a natural blend of merino, possum, and silk. Our natural fibres are really at the heart of what we do, and they’re chosen for their ecological benefits as well as their ability to safely return to nature at the end of their life. Any small fibres that shed from our 100% natural garments will not harm the environment.

Tackling the 7%

We believe 93% is a great start, but we want to do even better, so we’re tackling the 7% of garments that contain a small proportion of synthetic fibres such as Lycra and elastane. These synthetic fibres are mainly added for stretch or performance, but they are also present in some of the deadstock and recycled fabrics we use to progress our commitment to circularity.

Because they provide key performance and durability benefits, tackling synthetics isn’t as simple as just removing them from the products and carrying on – we need to find viable replacements, otherwise we risk reducing quality, and that’s something we never compromise on.

Research and development

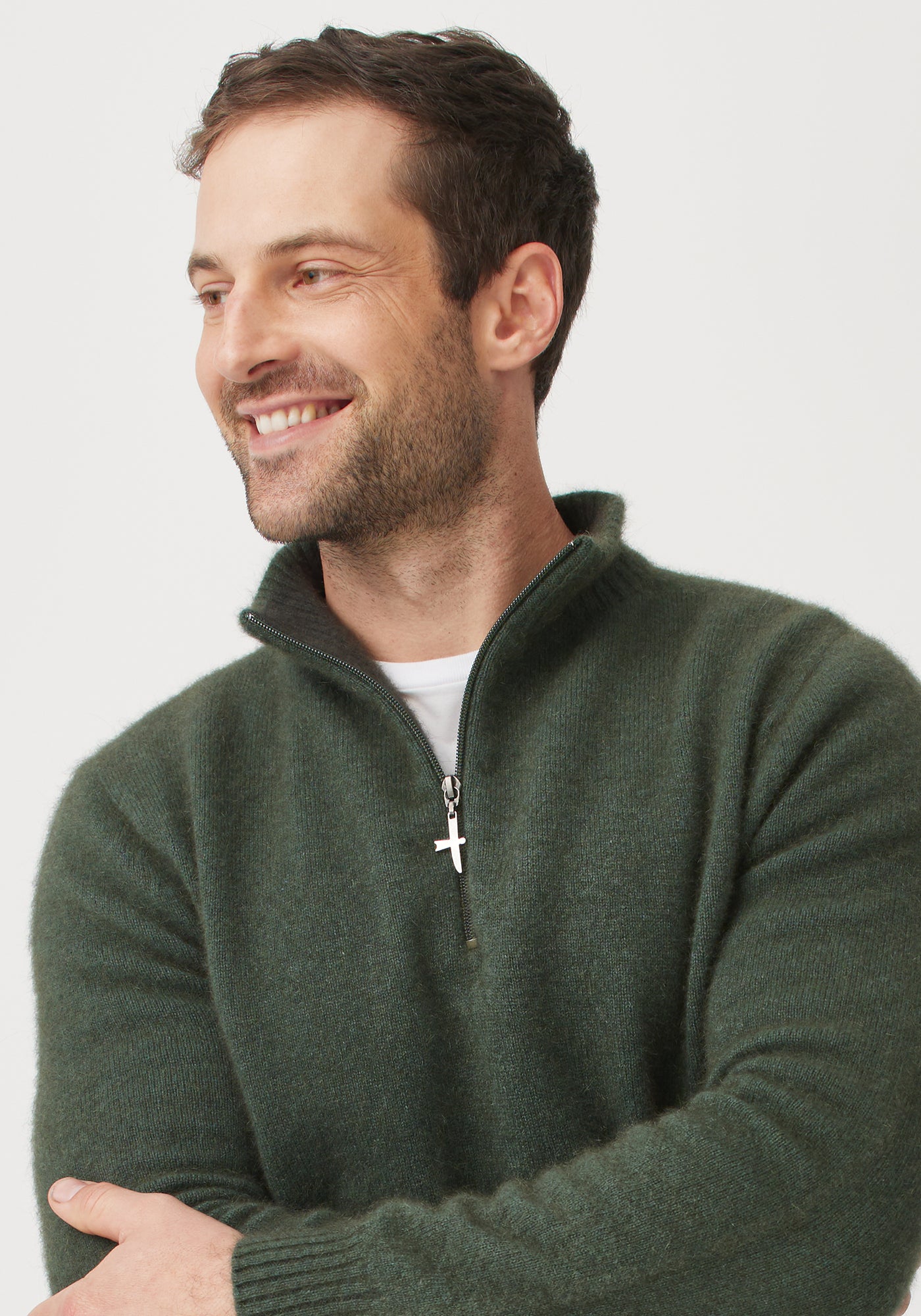

Finding replacements is an in-depth process, as we explored in our journal entry about finding a more ecologically beneficial alternative for the virgin plastic polybags we once used. We are exploring the landscape of innovative nature-based fibres and fabrics to see what’s out there. Currently we’re working on sourcing and testing natural threads for sewing our garments as well as investigating sourcing zips with a natural fibre zip tape. Once we have a number of options, we can then run tests to see how they perform in our products.

An example of this kind of testing is that which we carried out on our Rubbish Socks. After discovering that there was 20% nylon in them (added as a colour-matched carrier thread), we started sampling pairs containing no nylon at all, and other pairs containing nylon in only the heel and the toe. It’s an ongoing process as we work to find the best solution without losing any of the quality and durability our customers trust us to provide.

As we research and test, whether for our socks or for other products in the 7%, questions we must consider include: How are these fibres or threads made? What’s the impact? Are they made to our social and environmental standards? Do they provide the same performance as synthetics? Are they as durable? Will using them in our products mean a compromise in quality?

Just as we did with our polybags, we’re certain we will find our way through and achieve our target, but in the meantime we’ve got a lot of work to do. As with all aspects of what we do at Untouched World, we will be transparent about how we’re progressing towards our goal of zero microplastics by 2030, so keep an eye out for updates.

To read about our shorter-term goals for 2024, head to our recent journal post. And get to know our fabrics in our deep dive for AW24.